Menene bambance-bambance da bambance-bambance tsakanin masu yankan milling na HSS da masu yankan niƙa na Carbide dangane da kayan, tsari, da aiki?A wanne yanayi ya kamata a yi amfani da kayan aikin HSS, kuma a waɗanne yanayi ya kamata a yi amfani da kayan aikin Carbide?

1. Bambance-bambance tsakanin HSS End Mill da Tungsten Carbide End Mill

1. Bambance-bambancen kayan aiki.

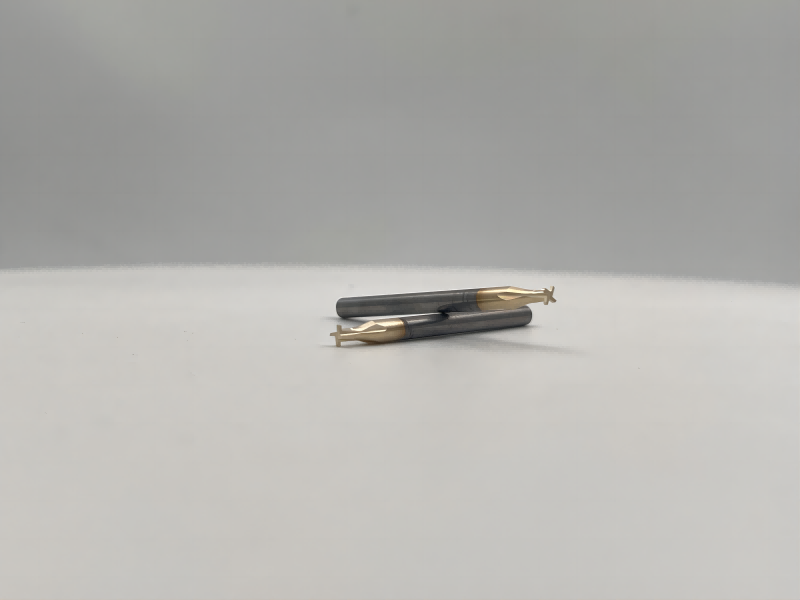

HSS End Mill an yi shi da sandunan ƙarfe masu sauri, yawanci ana yin su da kayan M42, tare da abun ciki na vanadium wanda bai wuce 1% ba da abun ciki na cobalt na 8%.

Abubuwan da aka bayar na Carbide End Mill kayan aikin CNC ne wanda Tungsten Carbide ya yi.

2. Bambance-bambance a cikin aikin sarrafawa.

Kayan aikin yankan HSS suna da taurin zafin ɗaki na 62-70HRC, yayin da kayan yankan carbide ke da taurin zafin ɗaki na 89-94HRC.A zafi juriya na kayan aiki surface kai 1000 ℃, da kuma yankan gudun carbide za a iya ƙara da 50-100% idan aka kwatanta da HSS.Za'a iya inganta ƙarfin kayan aiki ta sau 2-10;Idan aka kwatanta da kayan aikin HSS, kayan aikin yankan carbide sun fi dacewa da sauri, inganci, da sarrafa zafin jiki.

kayan aikin yankan carbideHigh narkewa batu, high tauri, high na roba modulus, mai kyau sinadaran kwanciyar hankali da thermal kwanciyar hankali.Taurinsa, juriya da juriya na zafi sun fi kayan aikin yankan HSS kyau.

Hardness: Carbide kayan aiki 89 ~ 94HRC.HSS kayan aikin 62-70HRC.

Juriya mai zafi: Kayan aikin Carbide a 800-1000 ℃, kayan aikin HSS a 600-650 ℃.

Juriya Sawa: Juriya na kayan aikin Carbide shine sau 15-20 fiye da na kayan aikin HSS.

Gudun Yanke: Gudun kayan aikin Carbide shine sau 4-10 na kayan aikin HSS.

2. Yaushe HSS milling cutters daCarbide milling cuttersa yi amfani?

Ba duk yanayin sarrafawa ba ne ke buƙatar amfani da masu yankan milling na Carbide, saboda sarrafa farashin kowane tsarin sarrafawa ya bambanta, kuma ana iya amfani da kayan aikin sassa daban-daban cikin sassauƙa.

Lokacin da ƙarfin injin ɗin ya yi ƙasa, buƙatun daidaiton mashin ɗin ba su da yawa, kuma ana amfani da kayan aikin ƙarancin ƙarewa, yawancin samfuran ƙanƙara ne, kuma riba ta ragu, ana iya amfani da kayan yankan HSS.Ko da wasu abubuwan da ke da wahalar injin, kayan aikin HSS kuma na iya zama ƙware, amma saurin yanke su, juriya, da dorewa ba su isa ba.

Ina tsammanin a mafi yawan lokuta, musamman ma a lokacin high-gudun, inganci, da kuma manyan machining, yana da muhimmanci a yi amfani da kayan aikin yankan carbide, har ma da yumbu da kayan aikin lu'u-lu'u: babban farashin kayan aiki guda ɗaya ba dole ba ne ya zama babban farashin sarrafawa. ;A yawancin lokuta, yin amfani da kayan aikin "masu tsada" yana haifar da ƙananan farashin sarrafawa fiye da kayan aikin HSS.

Lokacin aikawa: Juni-03-2023