Tare da ci gaban kimiyya da fasaha na zamani, ana amfani da kayan aikin injiniya da yawa tare da taurin gaske, yayin da fasahar jujjuyawar gargajiya ba ta da ƙarfi ko kuma ba za ta iya cimma sarrafa wasu kayan tauri ba kwata-kwata.Mai rufi carbide, tukwane, PCBN da sauran superhard kayan aiki kayan da high zafin jiki taurin, sa juriya da thermochemical kwanciyar hankali, wanda ya samar da mafi asali da ake bukata domin yankan high taurin kayan, kuma sun samu gagarumin amfani a samar.Abubuwan da babban kayan aiki ke amfani da shi da tsarin kayan aiki da sigogin lissafi sune abubuwan asali don gane juzu'i mai wuya.Don haka, yadda za a zaɓi kayan kayan aiki mai ƙarfi da ƙira ingantaccen tsarin kayan aiki da sigogin geometric yana da mahimmanci don cimma juzu'i mai ƙarfi!

(1) Ruwan siminti mai rufi

Aiwatar da ɗaya ko fiye da yadudduka na TiN, TiCN, TiAlN da Al3O2 tare da juriya mai kyau akan kayan aikin carbide da aka yi da siminti tare da tauri mai kyau, kuma kauri na rufin shine 2-18 μm.Rubutun yawanci yana da ƙarancin ƙarancin thermal fiye da kayan aikin kayan aiki da kayan aiki, wanda ke raunana tasirin thermal na kayan aikin;A gefe guda, yana iya inganta haɓakar juzu'i da mannewa a cikin tsarin yankewa da rage haɓakar yanke zafi.

Ko da yake PVD shafi ya nuna da yawa abũbuwan amfãni, wasu coatings kamar Al2O3 da lu'u-lu'u ayan dauko CVD shafi fasaha.Al2O3 wani nau'i ne na sutura tare da tsayayyar zafi mai ƙarfi da juriya na iskar shaka, wanda zai iya raba zafi da aka haifar ta hanyar yanke daga takamaiman kayan aiki.CVD fasaha fasahar kuma iya hade da abũbuwan amfãni daga daban-daban coatings don cimma mafi kyau yankan sakamako da saduwa da bukatun yankan.

Idan aka kwatanta da kayan aikin carbide da aka yi da siminti, kayan aikin simintin siminti mai rufi sun inganta sosai cikin ƙarfi, tauri da juriya.A lokacin da juya workpiece tare da taurin na HRC45 ~ 55, low-cost rufi cemented carbide iya gane high-gudun juya.A cikin 'yan shekarun nan, wasu masana'antun sun inganta aikin kayan aiki masu rufi ta hanyar inganta kayan shafa da sauran hanyoyin.Alal misali, wasu masana'antun a Amurka da Japan amfani da Swiss AlTiN shafi abu da kuma sabon shafi jadadda mallaka fasaha don samar da rufi ruwan wukake da taurin kamar yadda HV4500 ~ 4900, wanda zai iya yanke HRC47 ~ 58 mutu karfe a gudun 498.56m / min. .Lokacin da yawan zafin jiki ya kai 1500 ~ 1600 ° C, taurin har yanzu baya raguwa kuma baya oxidize.Rayuwar sabis na ruwan wukake shine sau hudu na babban ruwa mai rufi, yayin da farashin kawai 30% ne, kuma adhesion yana da kyau.

(2) Kayan yumbu

Tare da ci gaba da haɓaka abubuwan da ke tattare da shi, tsarin da tsarin aiki, musamman ma ci gaban nanotechnology, kayan aikin yumbu suna ba da damar ƙarfafa kayan aikin yumbu.Nan gaba kadan, yumbu na iya haifar da juyin juya hali na uku a yankan bayan karfe mai sauri da siminti carbide.Kayan aikin yumbu suna da abũbuwan amfãni na high taurin (HRA91 ~ 95), babban ƙarfi (ƙarfin lankwasawa 750 ~ 1000MPa), mai kyau lalacewa juriya, mai kyau sinadaran kwanciyar hankali, mai kyau adhesion juriya, low gogayya coefficient da low price.Ba wai kawai ba, kayan aikin yumbu kuma suna da taurin zafin jiki mai girma, wanda ya kai HRA80 a 1200 ° C.

A lokacin yankan al'ada, kayan aikin yumbu yana da tsayin daka sosai, kuma saurin yankan sa na iya zama sau 2 ~ 5 fiye da na siminti carbide.Ya dace musamman don sarrafa kayan aiki mai ƙarfi, gamawa da mashin ɗin sauri.Yana iya yanke ƙarfe iri-iri da taurin simintin ƙarfe tare da taurin har zuwa HRC65.Abubuwan da aka fi amfani da su sune tukwane na tushen alumina, tukwane na silicon nitride, cerimeti da whisker masu tauri.

Kayan aikin yumbu na tushen Alumina suna da taurin ja fiye da siminti carbide.Gabaɗaya, yankan gefen ba zai haifar da nakasar filastik a ƙarƙashin yanayin yanke mai sauri ba, amma ƙarfinsa da taurinsa suna da ƙasa kaɗan.Domin inganta taurinsa da juriya na tasiri, ana iya ƙara cakudar ZrO ko TiC da TiN.Wata hanya kuma ita ce ƙara tsarkakakken ƙarfe ko siliki carbide wuski.Baya ga babban taurin ja, silikon nitride tushen yumbu shima yana da tauri mai kyau.Idan aka kwatanta da tukwane na tushen alumina, rashin amfanin sa shine yana da sauƙi don samar da yaduwar zafin jiki yayin sarrafa ƙarfe, wanda ke ƙara lalacewa kayan aiki.Silicon nitride tushen tukwane ana amfani da su musamman don jujjuyawar ɗan lokaci da niƙa baƙin ƙarfe mai launin toka.

Cermet wani nau'i ne na kayan aiki na carbide, wanda TiC shine babban lokaci mai wuyar gaske (0.5-2 μm) An haɗa su tare da Co ko Ti binders kuma suna kama da kayan aikin carbide da aka yi da siminti, amma suna da ƙananan alaƙa, kyakkyawar gogayya da kyau. sa juriya.Zai iya jure wa zafin jiki mafi girma fiye da na al'ada cemented carbide, amma ba shi da tasirin tasirin simintin carbide, ƙarfin lokacin yankan nauyi da ƙarfi a ƙananan gudu da babban abinci.

(3) Cubic boron nitride (CBN)

CBN ne na biyu bayan lu'u-lu'u a cikin tauri da juriya, kuma yana da kyakkyawan yanayin zafi.Idan aka kwatanta da yumbu, juriyar zafinsa da kwanciyar hankali na sinadarai sun ɗan yi rauni, amma ƙarfin tasirinsa da aikin hana murƙushewa ya fi kyau.Yana da amfani ko'ina ga yankan taurare karfe (HRC ≥ 50), pearlitic launin toka baƙin ƙarfe, sanyi simintin ƙarfe da superalloy.Idan aka kwatanta da kayan aikin carbide da aka yi da siminti, za a iya ƙara saurin yanke shi da tsari ɗaya na girma.

Kayan aikin polycrystalline cubic boron nitride (PCBN) mai hade tare da babban abun ciki na CBN yana da tsayin daka, juriya mai kyau, ƙarfin matsawa da ingantaccen tasiri.Lalacewarsa shine rashin kwanciyar hankali na thermal da ƙarancin rashin kuzarin sinadarai.Ya dace da yankan allunan da ke jure zafi, simintin ƙarfe da ƙarfe na tushen ƙarfe.Abubuwan da ke tattare da barbashi na CBN a cikin kayan aikin PCBN ba su da yawa, kuma taurin kayan aikin PCBN da ke amfani da yumbu a matsayin mai ɗaure ba shi da ƙarfi, amma yana samar da ƙarancin kwanciyar hankali da ƙarancin ƙarancin sinadarai na tsohon kayan, kuma ya dace da yanke taurin ƙarfe.

Lokacin yankan baƙin ƙarfe mai launin toka da taurin ƙarfe, kayan aikin yumbu ko kayan aikin CBN za a iya zaɓar.A saboda wannan dalili, ya kamata a gudanar da bincike-binciken farashi da fa'ida don tantance wanda za a zaɓa.Lokacin da taurin yanke ya yi ƙasa da HRC60 kuma an karɓi ƙaramin adadin abinci, kayan aikin yumbu shine mafi kyawun zaɓi.Kayan aikin PCBN sun dace da yankan kayan aiki tare da taurin sama sama da HRC60, musamman don injina ta atomatik da ingantattun mashin ɗin.Bugu da kari, da saura danniya a kan workpiece surface bayan yankan tare da PCBN kayan aiki ne kuma in mun gwada da barga fiye da cewa tare da yumbu kayan aiki a karkashin yanayin da wannan flank lalacewa.

Lokacin amfani da PCBN kayan aiki don bushe yanke taurin karfe, ya kamata kuma a bi wadannan ka'idoji: zaɓi babban zurfin yankan gwargwadon yadda zai yiwu a ƙarƙashin yanayin da ƙarfin injin ya ba da damar, ta yadda zafin da aka haifar a cikin yanki zai iya yin laushi. karfe a gaban gefen gida, wanda zai iya rage lalacewa na kayan aikin PCBN yadda ya kamata.Bugu da ƙari, lokacin amfani da ƙananan zurfin yankan, ya kamata kuma a yi la'akari da cewa rashin ƙarfin wutar lantarki na kayan aikin PCBN na iya sa zafi a cikin yanki ya yi latti don yadawa, kuma yanki mai ƙarfi zai iya haifar da sakamako mai laushi na ƙarfe, Rage rage yawan zafin jiki. lalacewa na yanke baki.

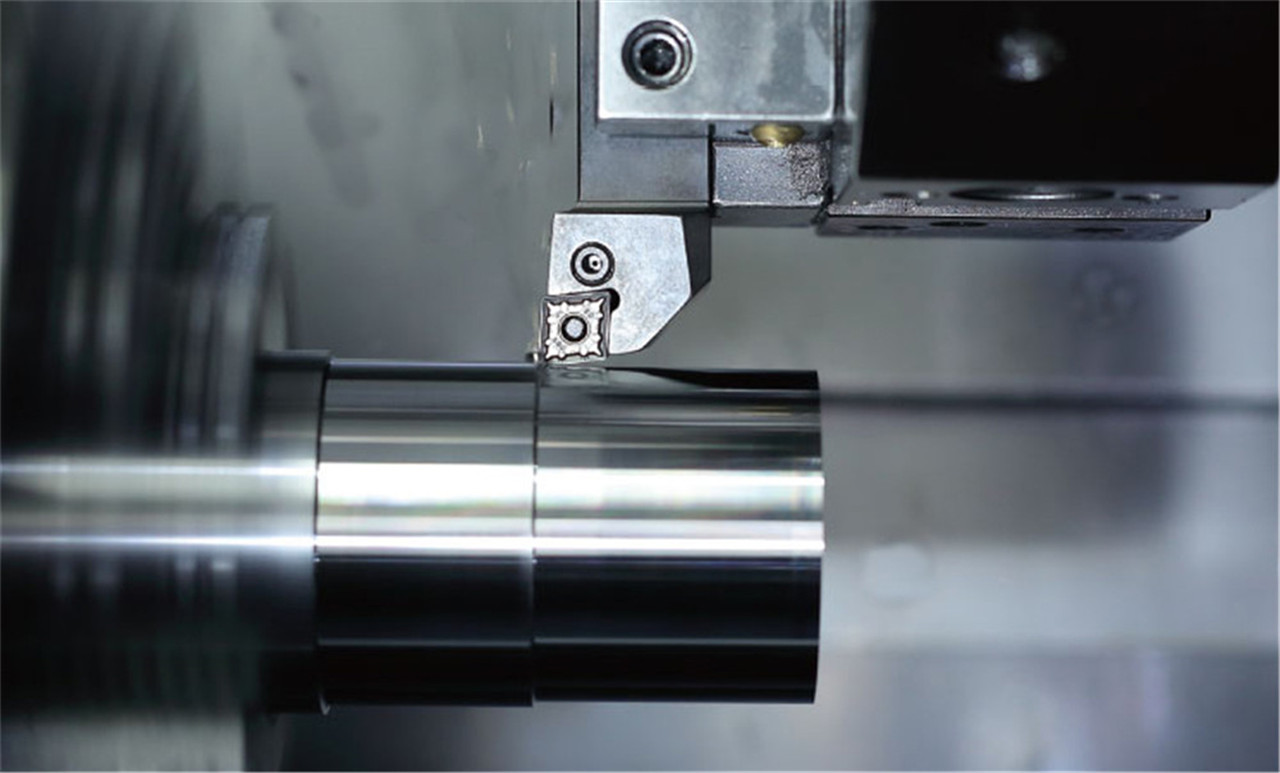

2. Tsarin ruwa da sigogi na geometric na kayan aiki masu ƙarfi

Ƙididdigar ma'auni na sifa da sigogi na geometric na kayan aiki yana da matukar muhimmanci don ba da cikakken wasa don yanke aikin kayan aiki.Dangane da ƙarfin kayan aiki, ƙarfin tip kayan aiki na nau'ikan nau'ikan ruwa daga sama zuwa ƙasa shine: zagaye, 100 ° lu'u-lu'u, murabba'i, 80 ° lu'u-lu'u, alwatika, 55 ° lu'u-lu'u, lu'u-lu'u 35 °.Bayan an zaɓi kayan ruwa, za a zaɓi siffar ruwa tare da mafi girman ƙarfi.Har ila yau, ya kamata a zaɓi igiyoyin jujjuyawar ƙarfi gwargwadon iyawa, kuma ya kamata a yi aikin injin daɗaɗɗen madauwari da manyan radius radius.Radius na tip baka yana kusan 0.8 lokacin kammalawa μ Game da m.

Ƙaƙƙarfan ƙwanƙwasa ƙarfe suna da ja da ribbon mai laushi, tare da raguwa mai girma, mai sauƙin karya kuma maras ɗauri.Wurin yankan karfe mai tauri yana da inganci kuma gabaɗaya baya samar da tarin guntu, amma ƙarfin yankan yana da girma, musamman ma ƙarfin yankan radial ya fi babban ƙarfin yankan girma.Sabili da haka, kayan aiki yakamata suyi amfani da kusurwar gaba mara kyau (tafi ≥ - 5 °) da babban kusurwar baya (ao = 10 ° ~ 15 °).Babban kusurwar jujjuyawar ya dogara da rigidity na kayan aikin injin, gabaɗaya 45 ° ~ 60 °, don rage magana da kayan aiki da kayan aiki.

Lokacin aikawa: Fabrairu-24-2023