Kamar yadda aka sani, reaming shine tsari na ƙarshe a cikin tsarin rami.Idan wasu abubuwa sun shafe shi, da alama ƙwararrun samfuran da aka gama za su zama kayan sharar gida nan take.To, menene ya kamata mu yi idan muka fuskanci matsaloli?Kayan aikin yankan OPT sun tsara wasu batutuwa da matakan da suka taso a cikin aikace-aikacen aikace-aikacen Reamer, da fatan za ku iya samun wasu fahimta a cikin labarin.

1. Rashin ƙarancin ramin ciki

dalili

1.The yankan gudun ne ma high.

2.Zaɓin Yankan ruwa bai dace ba.

3.Babban karkataccen kusurwa na reamer yana da girma sosai, kuma yankan gefen reamer ba a kan wannan kewaye ba.

4.The reaming allowance ne mai girma, m ko kuma karami, kuma na gida surface ba a reamed.

5.The lilo karkata daga cikin yankan part na reamer wuce haƙuri, da yankan gefen ba kaifi, da kuma surface ne m.

6.The yankan gefen reamer ne da fadi da yawa.

7.Poor guntu cire a lokacin reaming.

8.Yawan lalacewa na reamer.

9.The reamer ne bruised, barin burrs ko chipping a gefen.

10.Akwai tarkacen tarkace akan yankan.

11.Due to abu constraints, shi ne bai dace da sifili digiri ko korau rake kwana reamers.

Matakan amsawa

1. Rage saurin yankewa.

2. Zaɓi Yanke ruwa bisa ga kayan aiki.

3. Rage babban kusurwar karkatacciyar hanya daidai kuma niƙa yankan daidai daidai.

4. Rage alawus din reaming daidai.

5. Haɓaka daidaito da ingancin matsayi na ƙasa kafin yin reaming ko ƙara iznin reaming.

6. Niƙa nisa na bel ɗin ruwa.

7. Rage adadin hakora a kan reamer bisa ga takamaiman yanayi, ƙara sarari don guntu riƙon tsagi, ko amfani da reamer tare da kusurwar ƙwaƙƙwaran ruwa don tabbatar da cire guntu mai santsi.

8. Sauya reamer akai-akai kuma cire wurin niƙa yayin niƙa ruwa.

9. Lokacin niƙa, amfani, da jigilar kayan reamer, yakamata a ɗauki matakan kariya don gujewa karo.

10. Ga magudanar da aka lalace, yi amfani da dutse mai kyau don gyara shi ko maye gurbinsa.

2. Ramin ciki zagaye

dalili

1. Reamer yayi tsayi da yawa kuma bashi da tsauri, yana haifar da girgiza yayin reaming.

2. Babban kusurwar karkatar da reamer ya yi ƙanƙanta sosai.

3. Yanke gefen reamer yana kunkuntar.

4. Yawan alawus alawus.

5. Akwai notches da ramukan giciye a saman rami na ciki.

6. Akwai ramukan yashi da ramuka a saman ramin.

7. The spindle hali ne sako-sako da, babu jagora hannun riga, ko yarda tsakanin reamer da jagora hannun riga ya yi girma, ko workpiece ne maras kyau bayan cire saboda m clamping na bakin ciki-bango workpieces.

Matakan amsawa

1. Reamers tare da rashin isasshen ƙarfi na iya amfani da reamers tare da farar haƙori mara daidaituwa, kuma shigar da reamer ya kamata ya yi amfani da haɗin kai mai ƙarfi don ƙara babban kusurwar karkatarwa.

2. Zaɓi ƙwararrun reamers kuma sarrafa haƙurin matsayi na rami na tsarin aiki na farko.Yin amfani da reamers marasa daidaituwa da yin amfani da dogon kuma madaidaicin hannayen riga;Zaɓi guraben da suka cancanta.

3.Lokacin da yin amfani da daidaitattun ramuka don ream mafi madaidaicin ramuka, ya kamata a gyara tsattsauran ramuka na kayan aikin injin, kuma matakin dacewa na hannun rigar jagora ya kamata ya zama mafi girma ko ya kamata a yi amfani da hanyoyin clamping masu dacewa don rage ƙarfi.

3. Layin tsakiya ba madaidaiciya

dalili

1. Matsalolin hakowa kafin yin reaming, musamman lokacin da buɗaɗɗen ƙarami, ba zai iya gyara lanƙwasawa ta asali ba saboda rashin ƙarfi na reamer.

2. Babban kusurwar karkatar da reamer ya yi girma da yawa;Jagoranci mara kyau yana sauƙaƙa wa mai reamer ya karkata daga alkibla yayin reaming.

3. Mazugi mai jujjuyawar sashin yanke ya yi girma da yawa.

4. Reamer yana motsawa a rata a cikin rami mai tsaka-tsaki.

5.Lokacin da ake yin reaming na hannu, ana yin amfani da karfi da yawa a waje guda, yana tilasta mai yin reamer ya karkata zuwa gefe ɗaya, yana lalata madaidaicin digiri 5 na reaming.

Matakan amsawa

1. Ƙara tsarin fadadawa ko ramuka masu ban sha'awa don gyara ramukan.

2. Rage babban kusurwar karkatarwa.

3. Daidaita reamer da ya dace.

4. Sauya reamer tare da sashin jagora ko yanki mai tsayi.

4. Ƙaruwa a buɗe ido

dalili

1. Ƙimar ƙira na diamita na waje na reamer yana da girma sosai ko kuma akwai burrs akan yankan gefen reamer.

2. Gudun yankan ya yi yawa.

3. Rashin cin abinci mara kyau ko izinin yin injina da yawa.

4. Babban kusurwar karkatar da reamer ya yi girma;Reamer ya lanƙwasa.

5. Akwai guntu guntu da aka haɗe zuwa gefen yankan yankan hinge.

6. Lokacin da ake niƙa, karkatar da jujjuyawar ƙwanƙolin yankan hinge ya wuce haƙuri.

7. Zaɓin Yankan ruwa bai dace ba.

8. Lokacin shigar da reamer, fuskar mazugi ba a tsaftace shi da tabon mai ko kuma akwai kututtuka da raunuka a saman mazugi.

9. Wutsiyar wutsiya na ƙwanƙwasa yana kashewa kuma yana tsoma baki tare da taper na tef ɗin bayan an shigar da shi a cikin mashin kayan aikin injin.

10. Ana lankwasa sandal ko ƙullun ƙullun ya yi yawa ko lalacewa.

11. Mai yawo na reamer baya sassauya.

12. Lokacin da axis ya bambanta da workpiece da hannun reaming, da karfi a kan duka biyu m, sa reamer zuwa hagu da dama.

Matakan amsawa

1. Ƙimar ƙira na diamita na waje na reamer yana da girma sosai ko kuma akwai burrs akan yankan gefen reamer.

2. Gudun yankan ya yi yawa.

3. Rashin cin abinci mara kyau ko izinin yin injina da yawa.

4. Babban kusurwar karkatar da reamer ya yi girma;Reamer ya lanƙwasa.

5. Akwai guntu guntu da aka haɗe zuwa gefen yankan yankan hinge.

6. Lokacin da ake niƙa, karkatar da jujjuyawar ƙwanƙolin yankan hinge ya wuce haƙuri.

7. Zaɓin Yankan ruwa bai dace ba.

8. Lokacin shigar da reamer, fuskar mazugi ba a tsaftace shi da tabon mai ko kuma akwai kututtuka da raunuka a saman mazugi.

9. Wutsiyar wutsiya na ƙwanƙwasa yana kashewa kuma yana tsoma baki tare da taper na tef ɗin bayan an shigar da shi a cikin mashin kayan aikin injin.

10. Ana lankwasa sandal ko ƙullun ƙullun ya yi yawa ko lalacewa.

11. Mai yawo na reamer baya sassauya.

12. Lokacin da axis ya bambanta da workpiece da hannun reaming, da karfi a kan duka biyu m, sa reamer zuwa hagu da dama.

5. Akwai gefuna a saman rami na ciki

Dalili

1. Yawan alawus alawus.

2. Yanke kwana na reamer yayi girma da yawa.

3. Yanke gefen reamer yayi kunkuntar.

4. Akwai pores, yashi ramukan, da wuce kima spindle runout a saman da workpiece.

Matakan amsawa

1. Rage alawus na reaming.

2. Rage kusurwar baya na sashin yanke.

3. Niƙa nisa na bel ɗin ruwa.

4. Zaɓi guraben da suka cancanta.

6. Karyewar hannu

Dalili

1. Reamer yayi tsayi da yawa kuma bashi da tsauri, yana haifar da girgiza yayin reaming.

2. Babban kusurwar karkatar da reamer ya yi ƙanƙanta sosai.

3. kunkuntar hinge yanke band;Matsakaicin izinin girbi.

4. Akwai notches da ramukan giciye a saman rami na ciki.

5. Akwai ramukan yashi da ramuka a saman ramin.

6. Ƙunƙarar sandar ƙwanƙwasa ta kasance sako-sako, ba tare da hannun rigar jagora ba, ko yarda tsakanin reamer da hannun rigar jagora ya yi girma da yawa, ko kuma saboda shigar da kayan aiki na bakin ciki.

7. A matsa ne ma m da workpiece deforms bayan cire.

Matakan amsawa

1. Rage saurin yankewa.

2. Zaɓi Yanke ruwa bisa ga kayan aiki.

3. Rage babban kusurwar karkatacciyar hanya daidai kuma niƙa yankan daidai daidai.

4. Rage alawus din reaming daidai.

5. Haɓaka daidaito da ingancin matsayi na ƙasa kafin yin reaming ko ƙara iznin reaming.

6. Niƙa nisa na bel ɗin ruwa.

7. Rage adadin hakora a kan reamer bisa ga takamaiman yanayi, ƙara sarari don guntu riƙon tsagi, ko amfani da reamer tare da kusurwar ƙwaƙƙwaran ruwa don tabbatar da cire guntu mai santsi.

8. Sauya reamer akai-akai kuma cire wurin niƙa yayin niƙa ruwa.

9. Lokacin niƙa, amfani, da jigilar kayan reamer, yakamata a ɗauki matakan kariya don gujewa karo.

10. Ga magudanar da aka lalace, yi amfani da dutse mai kyau don gyara shi ko maye gurbinsa.

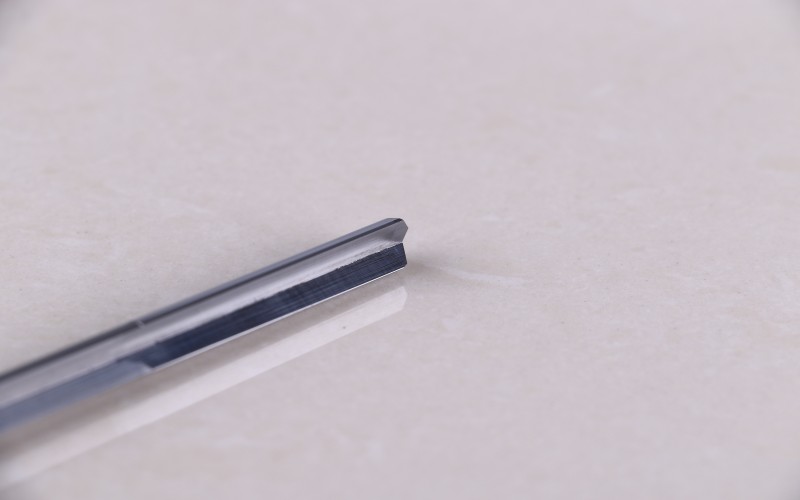

Tabbas, dole ne ku sami kyakkyawan mai samar da kayan aiki.Kayan aikin yankan OPT babban mai samar da kayayyaki ne wanda ya kware wajen samar da ma'auni daban-daban / mara inganci carbide reamerkumaPCD reamer

Shenzhen OPT Cutting Tool Co., Ltd. daya daga cikin manyan masana'anta a kasar Sin, ƙwarewa a cikin haɓakawa da samar da carbide da kayan aikin lu'u-lu'u na PCD.

Lokacin aikawa: Juni-16-2023