1.Cutting kayan aikin kayan aiki

Kayan aiki na yau da kullun a cikin niƙan kayan aiki sun haɗa da: ƙarfe mai sauri, ƙarfe mai ƙarfi foda, siminti carbide, PCD, CBN, cermet da sauran kayan haɓaka.Kayan aiki na ƙarfe mai saurin gudu suna da kaifi kuma suna da tauri mai kyau, yayin da kayan aikin carbide suna da babban taurin amma rashin ƙarfi.Yawan kayan aikin carbide da aka yi da siminti ya fi girma fiye da na kayan aikin ƙarfe mai sauri.Waɗannan kayan biyu sune manyan kayan aikin ƙwanƙwasa, reamers, masu yankan niƙa da famfo.A yi na foda metallurgy high gudun karfe ne tsakanin sama biyu kayan, kuma shi ne yafi amfani da Manufacturing m milling abun yanka da famfo.

Kayan aikin karfe masu saurin gudu ba su damu da karo ba saboda kyawun su.Duk da haka, kayan aikin carbide da aka yi da siminti suna da tsayin daka da raguwa, suna da matukar damuwa ga karo, kuma gefen yana da sauƙin tsalle.Don haka, yayin aikin niƙa, ya zama dole a mai da hankali sosai game da aiki da kuma sanya kayan aikin siminti na carbide don hana haɗuwa tsakanin kayan aikin ko faɗuwar kayan aikin.

Saboda daidaitattun kayan aikin ƙarfe masu sauri ba su da yawa, buƙatun su na niƙa ba su da yawa, kuma farashinsu bai yi yawa ba, masana'antun da yawa sun kafa nasu taron bitar kayan aikin don niƙa su.Koyaya, kayan aikin siminti na carbide galibi ana buƙatar aika su zuwa ƙwararrun cibiyar niƙa don niƙa.Bisa kididdigar da yawancin cibiyoyin niƙa kayan aiki, fiye da 80% na kayan aikin da aka aika don gyara kayan aikin carbide cemented.

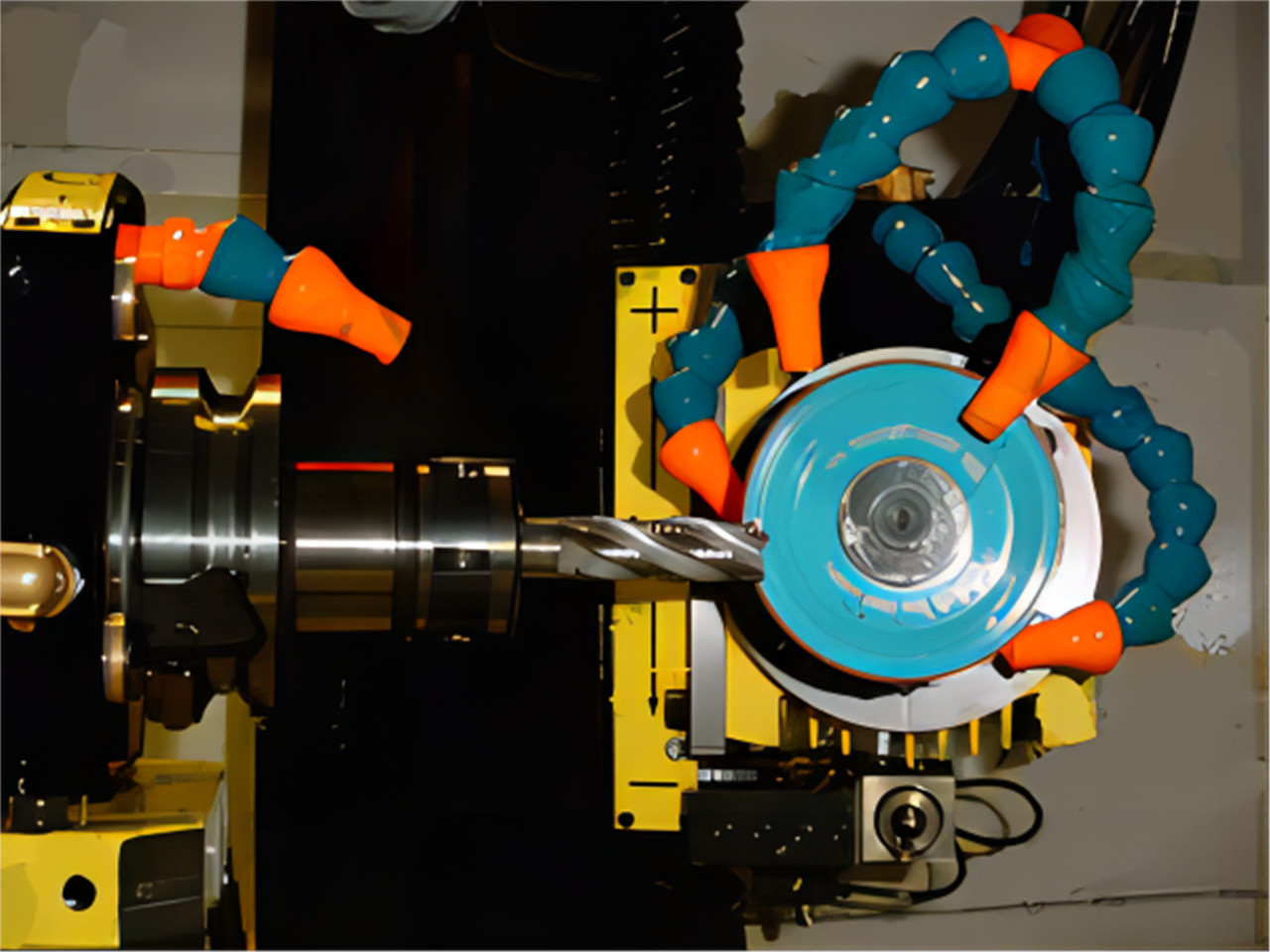

2. Yankan Tool grinder

Saboda kayan aikin kayan aiki yana da wuyar gaske, ana iya canza shi kawai ta hanyar niƙa.Kayan aiki na yau da kullun da ake amfani da su wajen kera kayan aiki da niƙa sun haɗa da:

(1).Injin tsinke: niƙa ragi ko baya na ƙwanƙwasa, injin ƙarewa da sauran kayan aikin.

(2).Angle grinder: Nika babban kusurwar juzu'i (ko kusurwar baya mai ma'ana) na bit ɗin rawar soja.

(3) .Trimming na'ura: Gyara gefen gefe na rawar rawar soja.

(4).Manual duniya kayan aiki grinder: nika m da'irar, tsagi, baya, saman kwana, m baki, jirgin sama, gaban fuska, da dai sauransu Ana amfani da sau da yawa ga kayan aiki tare da kananan yawa da kuma hadaddun siffar.

(5).Injin niƙa CNC: gabaɗaya haɗin axis guda biyar, tare da ayyuka da software ta ƙayyade.Ana amfani dashi gabaɗaya don kayan aikin niƙa tare da adadi mai yawa da ainihin buƙatun, amma ba rikitarwa ba, kamar su raƙuman ruwa, masana'anta na ƙarshe, reamers, da sauransu. .

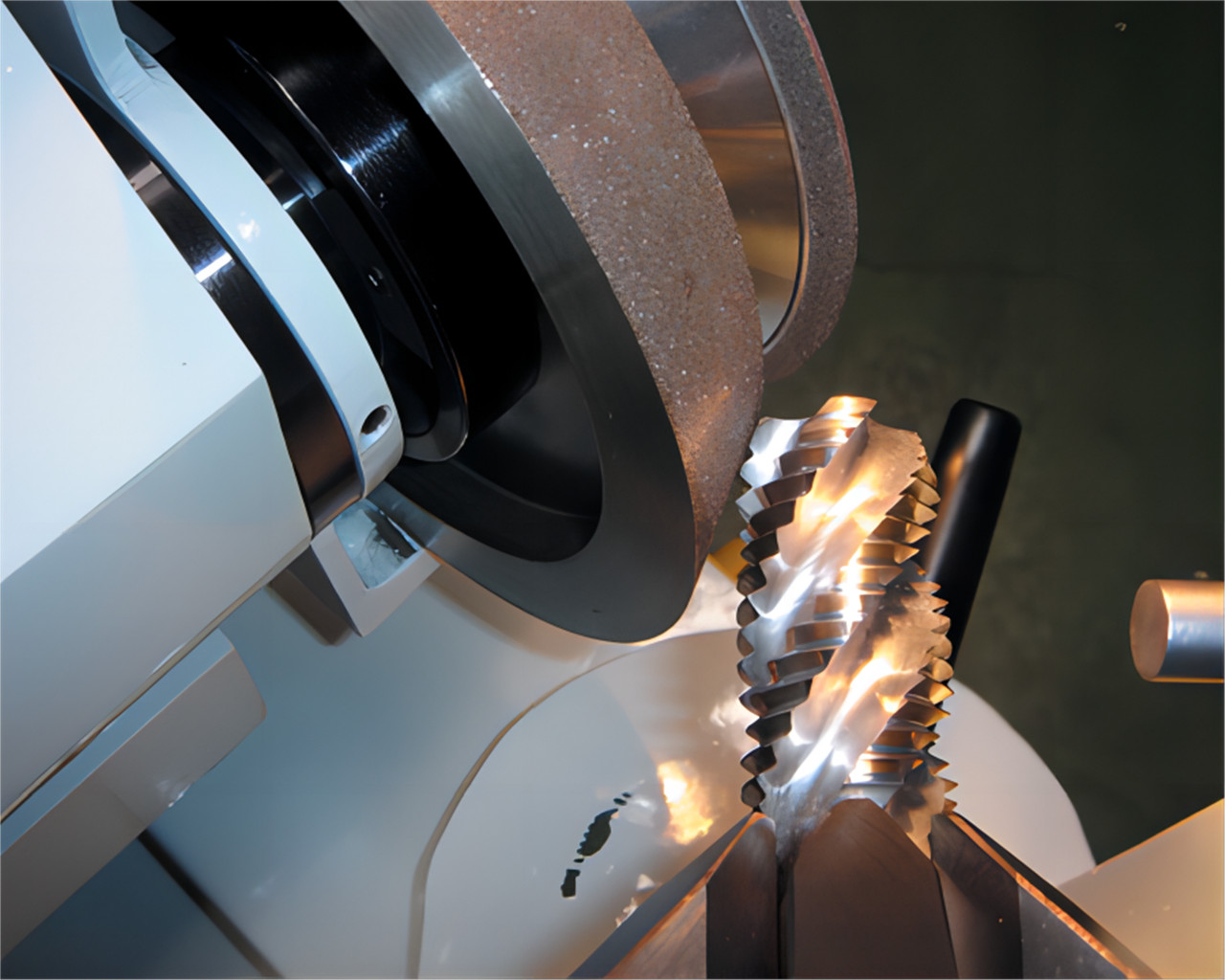

3.Dabarar niƙa

(1).Barbashi masu lalata

Nika dabaran abrasive barbashi na daban-daban kayan sun dace da nika kayan aikin na daban-daban kayan.Daban-daban na kayan aiki suna buƙatar nau'i-nau'i daban-daban na abrasive don tabbatar da mafi kyawun haɗuwa da kariyar gefen da ingantaccen aiki.

Alumina: ana amfani dashi don niƙa kayan aikin HSS.Dabarar niƙa tana da arha kuma mai sauƙin gyara ta zuwa sifofi daban-daban don niƙa hadaddun kayan aikin (corundum).

Silicon carbide: ana amfani da shi don gyara dabaran niƙa na CBN da ƙafafun niƙa na lu'u-lu'u.

CBN (cubic boron carbide): Ana amfani da shi don niƙa kayan aikin HSS.Babban farashi, amma mai dorewa.

A duniya, dabaran niƙa tana wakilta ta B, kamar B107, inda 107 ke wakiltar girman diamita barbasive.

Diamond: Ana amfani da shi don niƙa kayan aikin HM.Yana da tsada amma mai dorewa.

(2).Siffar

Domin sauƙaƙe sassa daban-daban na kayan aiki, injin niƙa ya kamata ya sami siffofi daban-daban.Wadanda akafi amfani dasu sune:

Parallel nika dabaran (1A1): nika saman kwana, m diamita, baya, da dai sauransu.

Dished dabaran nika (12V9, 11V9): nika karkace tsagi, babban da karin yankan gefuna na milling abun yanka, trimming a kwance gefen, da dai sauransu

Bayan an yi amfani da dabaran niƙa na ɗan lokaci, ana buƙatar gyara siffarsa (ciki har da jirgin sama, kwana da fillet R).Dole ne motar niƙa ta yi amfani da dutse mai tsaftacewa don cire kwakwalwan kwamfuta da aka cika tsakanin hatsin da ba a so ba don inganta ƙarfin niƙa na niƙa.

4.Ƙimar niƙa

Ko akwai ingantaccen tsarin niƙa kayan aiki shine ma'aunin don auna ko cibiyar niƙa ƙwararru ce.A cikin ma'auni na nika, ma'auni na fasaha na yankan kayan aiki daban-daban lokacin yankan kayan daban-daban an ƙayyade gabaɗaya, ciki har da kusurwar karkata, kusurwar sama, kusurwar gaba, kusurwar baya, chamfer, chamfer da sauran sigogi (a cikin simintin carbide bit. , Hanyar wucewa ta hanyar yankan ana kiranta "chamfer", kuma nisa na chamfer yana da alaƙa da kayan da za a yanke, gabaɗaya tsakanin 0.03-0.5Mm da 0.25Mm. ana kiransa "chamfer" kowane kamfani na ƙwararru yana da nasa ƙa'idodin niƙa da aka taƙaita tsawon shekaru.

Bambanci tsakanin HM bit da HSS bit:

HSS bit: kusurwar saman yana gabaɗaya digiri 118, wani lokacin ya fi digiri 130;Ruwa yana da kaifi;Abubuwan buƙatun don daidaito (bambancin tsayin ruwa, daidaitawa, runout kewaye) suna da ɗan ƙaramin ƙarfi.Akwai hanyoyi da yawa don gyara ruwa a kwance.

HM bit: babban kusurwa shine gabaɗaya digiri 140;Matsakaicin ramukan madaidaici yawanci digiri 130 ne, kuma ƙwanƙwasa gefuna uku gabaɗaya digiri 150 ne.Ruwa da tip (a gefen) ba su da kaifi kuma sau da yawa ana wucewa, ko ake kira chamfer da chamfer;Yana buƙatar babban daidaito.Sau da yawa ana gyara ɓangarorin kwance zuwa S-siffa don sauƙaƙe tsinke guntu.

Ƙungiya ta baya: Ƙaƙwalwar baya na ruwa yana da mahimmanci ga kayan aiki.Kusurwar baya yana da girma da yawa, kuma ruwa yana da sauƙi don tsalle da "soka";Idan kusurwar baya ta yi ƙanƙara, gogayya za ta yi girma da yawa kuma yanke ba zai yi kyau ba.

Kwancen baya na kayan aiki ya bambanta da kayan da za a yanke da nau'i da diamita na kayan aiki.Gabaɗaya magana, kusurwar baya tana raguwa tare da haɓaka diamita na kayan aiki.Bugu da ƙari, idan kayan da za a yanke yana da wuya, kusurwar baya zai zama karami, in ba haka ba, kusurwar baya zai fi girma.

5.Cutting Tools gano kayan aiki

Gabaɗaya kayan gano kayan aikin yankan sun kasu kashi uku: kayan saitin kayan aiki, majigi da kayan auna kayan aiki na duniya.An fi amfani da kayan aikin saitin kayan aiki don shirye-shiryen saitin kayan aiki (kamar tsayi) na kayan aikin CNC kamar cibiyoyin machining, da kuma gano sigogi kamar kusurwa, radius, tsayin mataki, da dai sauransu;Hakanan ana amfani da aikin na'urar don gano sigogi kamar kusurwa, radius, tsayin mataki, da sauransu. Duk da haka, biyun da ke sama ba za su iya auna kusurwar baya na kayan aiki ba.Kayan aikin aunawa na duniya na iya auna yawancin ma'auni na geometric na kayan aiki, gami da kusurwar baya.

Don haka, cibiyar niƙa ƙwararrun kayan aiki dole ne a sanye da kayan aikin auna kayan aiki na duniya.Duk da haka, akwai masu samar da irin waɗannan kayan aiki kaɗan, kuma akwai samfuran Jamus da Faransa a kasuwa.

6.Injiniyan nika

Mafi kyawun kayan aiki kuma yana buƙatar ma'aikata don yin aiki, kuma horar da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun masana'antu ta dabi'a ce ɗaya daga cikin mahimman hanyoyin haɗin gwiwa.Sakamakon koma bayan masana'antar kera kayan aiki a kasar Sin, da kuma karancin horon sana'o'i da fasahohi, horar da kwararrun masana aikin nika za a iya magance su ne kawai ta hanyar sana'ar kanta.

7. Kammalawa

Tare da kayan aikin niƙa, kayan gwaji da sauran kayan masarufi gami da ƙa'idodin niƙa, injinan niƙa da sauran software, ana iya fara aikin niƙa daidaitattun kayan aikin.Saboda wahalar aikace-aikacen kayan aiki, ƙwararrun cibiyar niƙa dole ne ta gyara tsarin niƙa akan lokaci bisa ga nau'in gazawar kayan aikin da za a niƙa, da bin diddigin amfanin kayan aikin.Cibiyar niƙa ƙwararrun kayan aiki dole ne koyaushe ta taƙaita gwaninta don sanya kayan aikin niƙa mafi kyau da ƙwarewa!

Lokacin aikawa: Fabrairu-24-2023