A halin yanzu, masana'antun sarrafa injuna na kasar Sin suna samun bunkasuwa cikin sauri, kuma ana amfani da wasu kayayyakin da ke da wahalar yankewa a masana'antar kayayyaki da injunan injuna.Don saduwa da buƙatun ci gaba na masana'antar sarrafa injuna na zamani, muna buƙatar amfani da wasu kayan aikin tare da ƙarfi mai ƙarfi da tauri mai kyau.Sabili da haka, ana amfani da kayan aiki mai wuyar gaske a hankali ga masana'antar sarrafa injina.Wannan labarin yana mayar da hankali kan aikace-aikacen kayan aiki masu wuyar gaske a cikin mashina don haɓaka kayan aikin kayan aiki mai wuyar gaske, don ba da ma'anar juna ga abokai a cikin masana'antu iri ɗaya.

Tare da saurin haɓaka fasahar masana'anta na zamani da gasa mai zafi na kasuwa, buƙatun masana'antar kera injiniyoyi don sassan kayan aikin injiniya kuma suna ƙaruwa, musamman don aiwatar da sassan injiniyoyi.Don haka, sabbin kayayyaki da kaddarori daban-daban sun fito a hankali a cikin al'umma.Waɗannan sabbin kayan ba wai kawai suna haifar da babban ƙalubale ga kayan aikin injin na gargajiya ba, har ma suna da wahalar sarrafawa.A wannan lokacin, kayan aikin yankan na zamani sun zama mabuɗin haɓaka masana'antar sarrafa injina, kuma babu shakka an yi amfani da kayan aikin kayan aiki masu ƙarfi ga sarrafa injinan zamani.

1. Tarihin ci gaba na kayan aiki mai wuyar gaske

A cikin 1950s, masana kimiyya na Amurka sun ɗauki lu'u-lu'u na roba, bond, da boron carbide foda a matsayin kayan albarkatun kasa, suna amsawa a ƙarƙashin yanayin zafi da matsa lamba, kuma sun sanya polycrystalline block a matsayin babban kayan kayan aiki.Bayan shekarun 1970, mutane a hankali sun ƙera kayan da aka haɗa, waɗanda ake samarwa ta hanyar haɗa lu'u-lu'u da siminti carbide, ko boron nitride da siminti carbide.A cikin wannan fasaha, ana ɗaukar carbide siminti a matsayin ƙasa, kuma an samar da lu'u-lu'u na lu'u-lu'u a saman ƙasa ta hanyar latsawa ko ƙwanƙwasa.Lu'u-lu'u yana da kauri kusan 0.5 zuwa 1 mm.Irin waɗannan kayan ba za su iya haɓaka juriya na kayan kawai ba, amma har ma yadda ya kamata magance matsalar cewa kayan gargajiya ba su da sauƙin waldawa.Wannan ya inganta kayan aiki mai wuyar gaske don shigar da matakin aikace-aikacen.

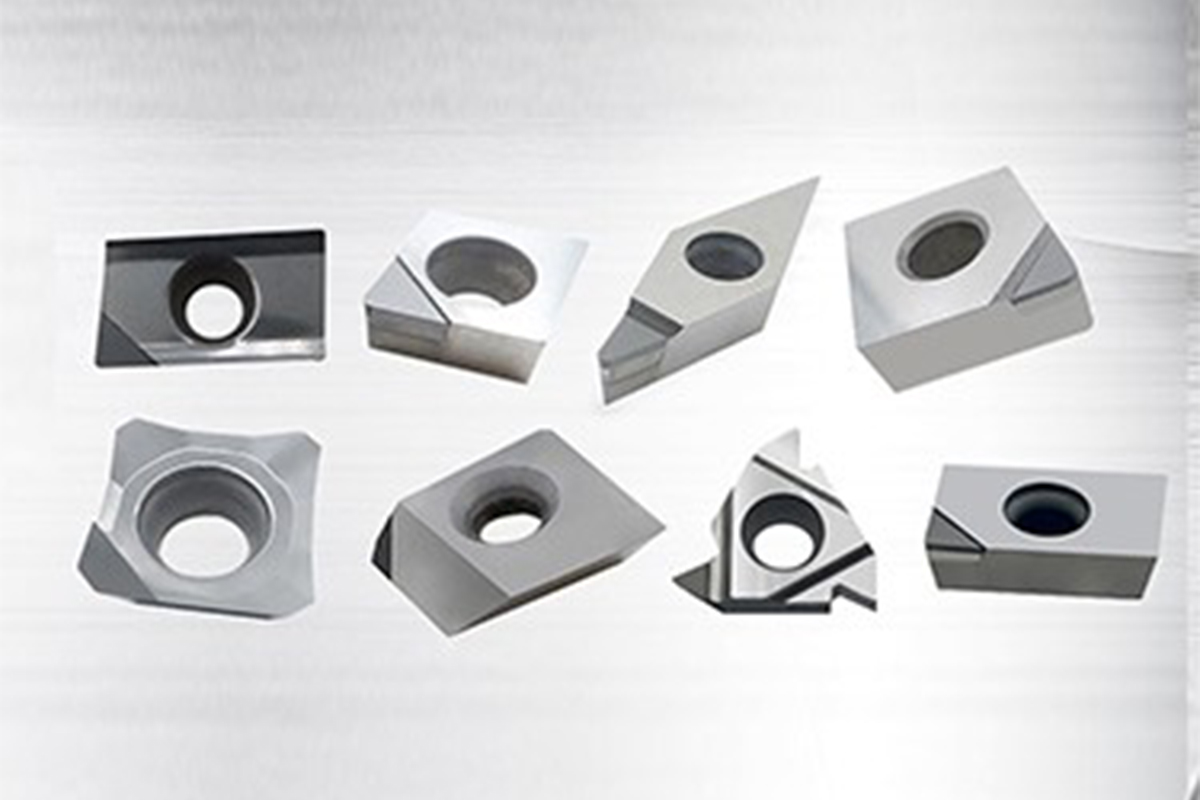

2. Aikace-aikace na kayan aiki mai wuyar gaske a cikin machining

(1) Aikace-aikacen kayan aikin lu'u-lu'u guda ɗaya

Lu'u lu'u-lu'u guda ɗaya yawanci ana raba zuwa lu'u-lu'u na roba da lu'u-lu'u na halitta.Gabaɗaya, idan an yi amfani da lu'u-lu'u lu'u-lu'u guda ɗaya don yin kayan aikin, dole ne a zaɓi lu'u-lu'u tare da girman barbashi mafi girma, taro mafi girma fiye da 0.1 g da tsayin diamita sama da 3 mm.A halin yanzu, lu'u-lu'u na halitta shine abu mafi wuya a cikin ma'adanai.Ba wai kawai yana da juriya mai kyau ba, har ma kayan aikin da aka yi da shi yana da kaifi sosai.A lokaci guda, yana da babban juriya na mannewa da ƙarancin ƙarancin thermal.Kayan aikin da aka sarrafa yana da santsi kuma yana da inganci.A lokaci guda, kayan aikin da aka yi da lu'u-lu'u na dabi'a yana da matukar tasiri da kuma tsawon rayuwar sabis.Bugu da ƙari, lokacin yankan na dogon lokaci, da wuya zai shafi sarrafa sassa.Ƙananan ƙarancin zafin jiki na iya yin tasiri mai kyau akan hana lalacewar sassa.

Lu'u-lu'u na halitta yana da fa'idodi da yawa.Ko da yake waɗannan fa'idodin suna da tsada, suna iya biyan buƙatun yawancin ayyukan yanke madaidaicin madaidaicin kuma ana amfani da su sosai a cikin yankan madaidaici da yankan madaidaici.Kamar madubin madubin da ke amfani da na'urorin sarrafa makamashin nukiliya da sauran fasahohin zamani, da na'urorin kewayawa na kasa da ake amfani da su a kan makamai masu linzami ko roka, da kuma wasu sassan agogo, na'urorin karafa da sauransu, sun yi amfani da wannan fasaha.

(2) Aikace-aikacen kayan aikin lu'u-lu'u na polycrystalline

Polycrystalline lu'u-lu'u yawanci ana kiransa lu'u-lu'u sintered.Yin amfani da lu'u-lu'u na polycrystalline don karafa irin su cobalt, ta hanyar yanayin zafi da yanayin zafi, zai sa yawancin lu'u-lu'u guda ɗaya na lu'u-lu'u polycrystalline ya zama daya, don haka samar da kayan aiki na polycrystalline.Taurin lu'u-lu'u na polycrystalline ya yi ƙasa da na lu'u-lu'u na halitta.Duk da haka, an samar da shi ta nau'in lu'u-lu'u na lu'u-lu'u, kuma babu wani yanayi cewa jiragen kristal daban-daban suna da ƙarfi da tauri daban-daban.Lokacin yankan, shingen da aka yi da lu'u-lu'u na polycrystalline yana da tsayin daka sosai ga lalacewar haɗari da kuma juriya mai kyau.Zai iya kiyaye kaifi mai kaifi na dogon lokaci.A lokaci guda, yana iya amfani da saurin yankan sauri lokacin yin injin.Idan aka kwatanta da kayan aikin carbide da aka yi da siminti na WC, kayan aikin lu'u-lu'u na polycrystalline suna da tsawon rayuwar sabis, sauƙin samun kayan roba da ƙananan farashi.

(3) Aikace-aikace na CVD lu'u-lu'u

Ana sarrafa kayan kayan aiki na lu'u-lu'u CVD a ƙarƙashin ƙananan matsa lamba, wanda shine babban bambanci daga fasahar PSC na gargajiya da fasahar PDC.CVD lu'u-lu'u baya ƙunshe da kowane abu mai ƙara kuzari.Ko da yake yana kama da lu'u-lu'u na halitta a wasu kaddarorin, har yanzu iri ɗaya ne da lu'u-lu'u na polycrystalline a cikin kayan, wato, ƙwayar abun da ke tattare da shi ba shi da tsari, rashin raguwar fashe, kuma suna da kaddarorin iri ɗaya tsakanin saman.Idan aka kwatanta da kayan aikin da aka yi ta hanyar fasahar gargajiya, kayan aikin da fasahar lu'u-lu'u ta CVD ta yi suna da ƙarin fa'ida, kamar surar kayan aiki da yawa, ƙananan farashin samarwa, da ɗigon ruwa iri ɗaya.

(4) Aikace-aikace na polycrystalline cubic boron nitride

Polycrystalline cubic boron nitride (PCBN) kayan aiki ne na kayan aiki na yau da kullun, wanda aka fi amfani dashi a cikin injina.Kayan aikin da aka yi tare da wannan fasaha yana da kyakkyawan taurin da juriya.Ba za a iya amfani da shi kawai a yanayin zafi mai girma ba, har ma yana da kyakkyawan juriya na lalata da kuma yanayin zafi.Idan aka kwatanta da PCD da kayan aikin PDC, kayan aikin polycrystalline cubic boron nitride kayan aikin har yanzu suna da ƙasa a cikin juriya, amma ana iya amfani da su akai-akai a 1200 ℃ kuma suna iya jure wasu lalatawar sinadarai!

A halin yanzu, polycrystalline cubic boron nitride ana amfani da shi ne a masana'antar kera motoci, kamar injunan mota, ramukan watsawa, da fayafai.Bugu da kari, kusan kashi biyar cikin biyar na sarrafa kayan aiki masu nauyi suma suna amfani da wannan fasaha.A cikin 'yan shekarun nan, tare da haɓaka fasahar kwamfuta da fasahar kayan aikin injin CNC, aikace-aikacen polycrystalline cubic boron nitride ya zama yaɗuwa sosai, kuma tare da aiwatar da ka'idodin mashin ɗin ci gaba kamar yankan saurin sauri, juyawa maimakon niƙa, kayan aiki. abu na polycrystalline cubic boron nitride a hankali ya haɓaka zuwa wani muhimmin abu a cikin sarrafa jujjuyawar zamani.

3. Takaitawa

Yin amfani da kayan aiki mai wuyar gaske a cikin injina ba wai kawai inganta inganci da inganci na injina ba, har ma yana taka muhimmiyar rawa wajen haɓaka masana'antar sarrafa injina.Sabili da haka, don haɓaka ci gaban masana'antar sarrafa kayan aikin injiniya, ya zama dole a ci gaba da ƙarfafa bincike na kayan aiki masu wuyar gaske, da cikakken fahimtar ilimin da ke da alaƙa da kayan aiki mai ƙarfi, da ƙarfafa aikace-aikacen aikace-aikacen, ba wai kawai don haɓaka ingancin kayan aikin ba. ma'aikata, amma kuma don ƙarfafa aikace-aikacen kimiyya da fasaha don inganta kayan aikin kayan aiki masu wuyar gaske, ta yadda za a gane haɓakar haɓakar masana'antar sarrafa injiniyoyi.

Lokacin aikawa: Juni-03-2019